Transformation

Above you see my vision of how the sculpture would look like, should be located and interact with nature. Impressive enough, this is a rendering simulation in summer 2020 .. half a year before I got the sculpture on my table. Special thanks to Designer Stefanie Naiser who executed all the digital stuff and who was a great consultant for my work.

State of the Art digital prototyping allows a lot of degrees of freedom to develop, improve, optimize 3D bodies or create them just purely computer-based. In my case I joined several key technologies to digitally prepare and understand the object properties in glass.

Steps are:

-

Laser-based measurement of ceramic object to create a numeric 3D model by company NeuDing, Wuppertal, Germany

-

Creation of a polygon mesh out of 3D numeric data. This is a computer based surface optimization by using polygon areas to iterate final surface.

-

Simplification of polygon mesh under spline criteria (mathematical surface smoothing) without changing object characteristics

-

Digital repair of surface inconsistencies which stem from ceramics original (edge breakouts, bumps). This includes the capability to create new object borders and edges which are filled by polygons to create a new, final 3D model

-

Rendering of object surfaces and core properties of glass body under different local and physical conditions (illumination situation, surface treatment, refractive index of glass)

-

3D Printing model in PMMA (acrylic plastic) and refinement by manual grinding (removing printing artefacts)

-

Creation of a silicon form based upon final acrylic plastic sculpture, executed by Lhotsky s.r.o., CZ

-

Full glass foundry process, executed by Lhotsky s.r.o., Czech Republic (www.lhotsky.cz)

Designer Stefanie Naiser deeply supported most of the above steps. Sabine Classen facilitated my connection to company NeuDing who contributed key modelling transfer techniques.

More details below ...

Laser-based measurement of ceramics object to create a numeric 3D model by company NeuDing, Wuppertal, Germany

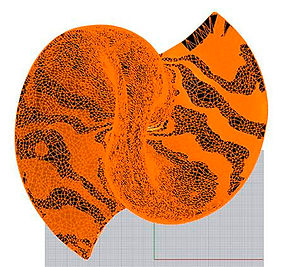

data points of laser scan demonstrated. Zebra pattern to judge quality of curvature quality

Creation of a polygon mesh out of 3D numeric data, digital stretch and shrink operation to final dimension. Final height: 30 cm

computer-generated polygons to approach objekt surface as area model

Simplification of polygon mesh under spline criteria (mathematical surface smoothing) without changing object characteristics

See data reduction by larger polygons while getting better smoothness under spline criteria. Zebra pattern again is demonstrating smoothing operation

Digital repair of surface inconsistencies which stem from ceramics original (edge breakouts, bumps)

demonstrating capability to create edges out of original body and fill with polygon meshes to create a new, final body

Rendering of object surfaces and core properties of glass body under different local and physical conditions (light situation, surface treatment, refractive index of glass)

Rendered in Steel as a first shot

Rendered in standard borosilicate glass versus diamond refractive index. Key learning is that higher refractive index leads to more light and internal reflections in glass core. This made my decision to use lead glass.

Spinning Triangle (ceramics) is now morphing into Crazy Diamond (glass)

Rendered in frosted surface. Interaction with ambient colors. Checking target environment. First confirmation of target properties of reflection and transmission effects when using frosted glass.

3D printing model in PMMA (acrylic plastic) and refine by manual grinding (removing printing artefacts)

Surface quality and grinding finishing

Finished model ready to ship to Lhotsky s.r.o., CZ. Copied by silicone form for lost form molding

Full glass foundry process, executed by Lhotsky s.r.o., Czech Republic

glass casting, fresh out of kiln, first rough finish

first and second round of acid polishing, delivery state